Hello and welcome!

If you’ve not been following along with this soapmaking series you might want to read Part I and Part II before you continue with this page.

In Part I we established that “soap is made by combining fats or oils with an alkali, such as lye.” In this post I will write about some ingredient that can be used and give you a recipe that I have used many times.

LYE

As I mentioned in Part I there are two types of lye – Sodium Hydroxide (NaOH) and Potassium Hydroxide (KOH). While either can be used to make soap, they are not interchangeable. They make different types of soap and though they could be mixed with the same fats or oils the recipe would require a different amount of sodium hydroxide than potassium hydroxide. The recipe that I will give you uses sodium hydroxide.

Here in the US sodium hydroxide might be a bit hard to find. It used to be sold commonly as a drain cleaner and some places like Walmart and Ace Hardware still carry it according to their websites. If you do decide to buy lye that is sold as drain cleaner just make sure it says “pure lye” or something similar on the label. You can also find it online at soapmaking supply sites like this. You will likely find that lye sold as drain cleaner is less expensive than lye sold for soapmaking. (I am not affiliated with, nor do I receive anything from, the above businesses. I just wanted to point you in the right direction.)

Water/Liquid

Since the lye that we use comes in the form of either beads or flakes we need to mix it with liquid to begin the chemical process before mixing it with the fats or oils. Basic recipes generally use water as the liquid with some calling for distilled water. I’m not sure why it would be necessary to buy distilled water since other liquids could be substituted. In the past I have used various herbal teas and coffee as liquids in my soap and though they each react differently with the lye they have all made good soaps. When mixing lye with water I am cautious not to use water that has been treated with chemicals such as chlorine or fluoride, therefore I use a purified water.

Fats and Oils

Pretty much any animal fat or vegetable oil can be combined with lye to make soap, but all fats are not created equal. The type of soap and the amount of lye it takes to saponify (turn it into soap) will vary depending on the fatty acid profile of each oil. To keep this simple, for those who just want to learn to make soap, I’m not going to go into all the math and science behind it but if you want to learn more you can do an internet search for ‘saponification chart’ and will you find many sites that will explain.

In commercial soap making common oils are beef tallow, coconut oil and palm oil but for those making their own soap the options range from the very frugal using rendered bacon grease (I’ve done that) or straining oil that you have used for deep frying to purchasing high end organic and sometimes even rare oils.

I don’t think there is any one oil that makes the perfect soap, however we will all have a different idea of what the perfect soap is. While it is possible to make a soap with just one oil, generally a combination of different fats and oils are used to balance the qualities of the soap. Some recipes will have six or more oils in varying amounts. The recipe that I give below uses just two oils. The coconut oil that makes a very hard and cleansing (drying) bar of soap along with a big bubbly lather has been balanced with olive oil which makes a soft soap that is more conditioning and less drying.

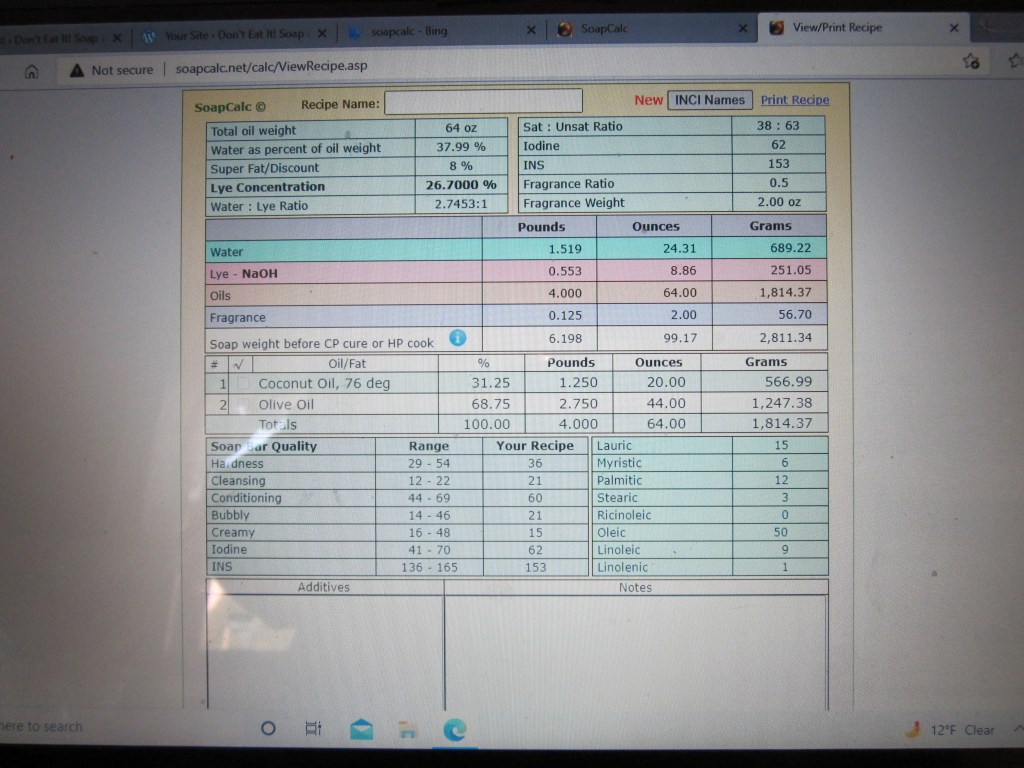

I do formulate my own recipes using this soap calculator. It looks pretty complicated but once I tell it the fats that I want to use and the amounts it will show me a page like the one below which is the recipe. (Feel free to hop over to that soap calculator and play with it and let me know if you have any questions.)

Not only does it tell me the amount of each ingredient I will need (in pounds, ounces and grams) it also tells me the qualities I can expect from this recipe.

Below is the recipe we will use in Part IV of this series. I wrote the recipe for a large batch using 4 lbs. (1814.37 grams) of fats/oils, which is what I made, but also broke it down into a (small) one lb. (453.59237 gram) batch for those who don’t want to start out that big. It is a simple recipe. The oils can be found on grocery store shelves (at least here in the US). It does not call for extras like fragrance or colorants, which are totally unnecessary. If you do decide to add a fragrance or essential oil to this recipe you would need 2 ounces for the large batch or .5 ounce for the small batch.

Soap Recipe – Large batch (Makes about 18 – 20 average size bars.)

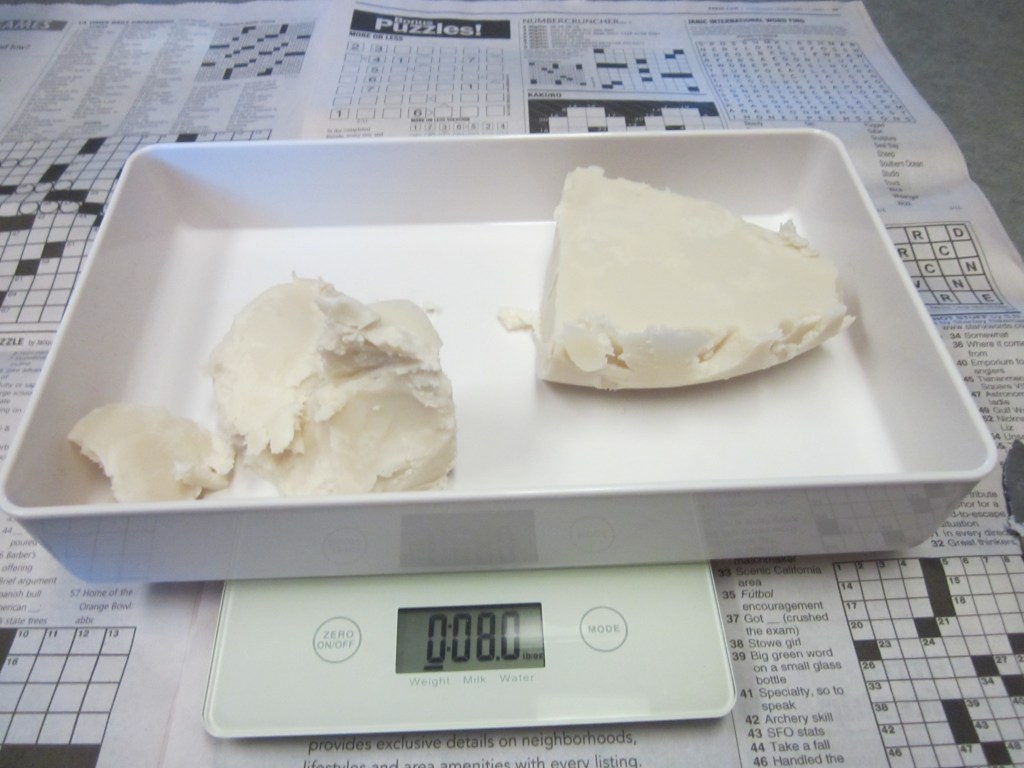

Coconut oil – 20 ounces (1 lb. 4oz.) (566.99 grams)

Olive Oil – 44 ounces (2 lbs. 8oz.) (1247.38grams)

Sodium Hydroxide (NoAH) – 8.86 ounces (251.05 grams)

Water – 24.3 ounces (1lb. 8.3oz) (689.22 grams)

Soap Recipe – Small Batch (Makes 4-6 average size bars.)

Coconut Oil – 5 ounces (141.75 grams)

Olive Oil – 11 Ounces (311.84 grams)

Sodium Hydroxide (NoAH) – 2.21 ounces (62.76 grams)

Water – 6 Ounces (172.36 grams)

Our next step (Part IV) will be the actual process for making the soap. Now while you make sure you have all the equipment and ingredients you need; I will work on Part IV. We’ll meet back here soon 🙂

Thanks for reading and if you have any questions, please leave them in the comments section below.